2025-09-09 14:21:04 source:sma

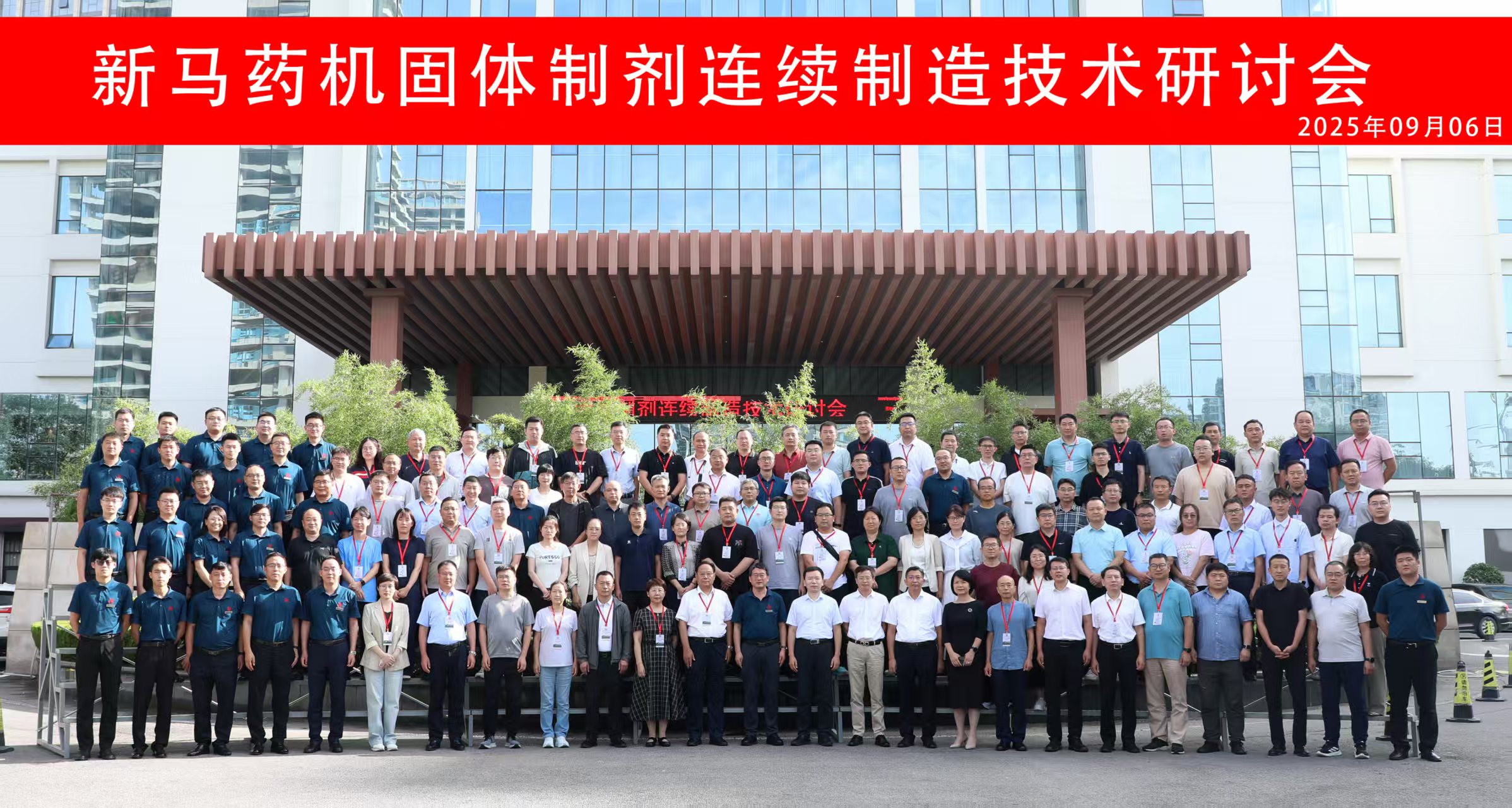

On September 6, 2025, SHANDONG SMA Pharmatech Co., Ltd. successfully held the "Seminar on Continuous Manufacturing Technology for Solid Dosage Forms" in Zibo, Shandong. The seminar invited more than 50 enterprises and over 120 distinguished guests and leaders in the industry to gather together, and in-depth exchanges and discussions were conducted focusing on the cutting-edge trends and development paths of continuous manufacturing technology for solid dosage forms.

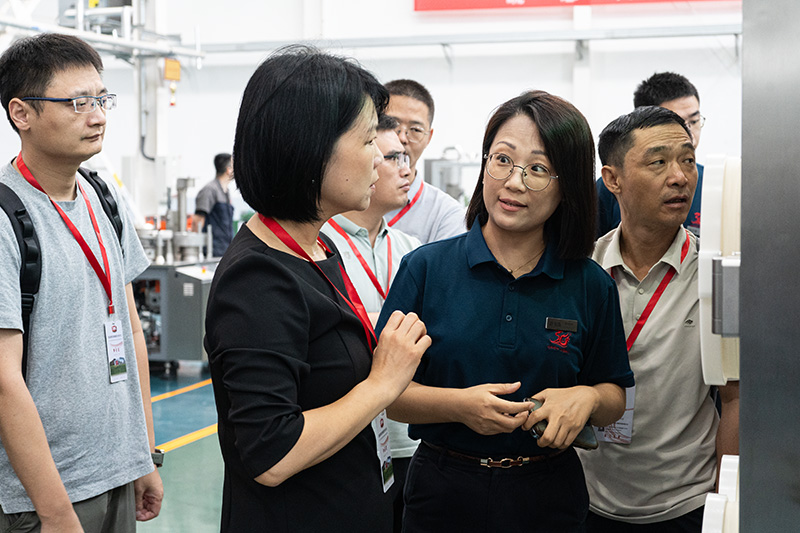

This seminar offered a rich agenda and diverse formats. In the morning, the participating guests visited SMA Company's modern production workshop and its 2,000㎡ GMP-compliant laboratory together, gaining an on-site understanding of the company's latest achievements and application practices in the fields of solid dosage form equipment and continuous manufacturing. Inside the continuous manufacturing room, the guests, through on-site observation of the production operation of the continuous manufacturing platform and on-site technical explanations, clearly witnessed the complete continuous production process from raw material powder to coated tablets. This fully demonstrated SMA's capabilities and accumulated experience in advancing continuous manufacturing technology from R&D to industrial application.

In the academic exchange session held in the afternoon, Yin Wenping, Chairman and General Manager of SMA, delivered the opening remarks. In his speech, he reviewed the company's 30-year development journey since its establishment in 1995, and emphasized that SMA has always adhered to the technological innovation concept of "Innovation, Rigor, Professionalism and Excellence". At present, the company has obtained a number of domestic exclusive product technologies, and has achieved breakthroughs in many domestic firsts, breaking the market monopoly of various European and American products. Meanwhile, in the field of continuous manufacturing, a number of continuous manufacturing equipment have been put into operation at customers' sites, and a number of products have adopted continuous manufacturing technology for process research, accumulating a wealth of process and practical experience.

At this seminar, Wang Xianqiang, Deputy Director of the Administrative Committee of Zibo High&New Tech Zone, was specially invited to deliver a thematic report titled Overview of the Development and Policies of the Pharmaceutical Industry in Zibo High&New Tech Zone, which conducted an in-depth analysis of the development opportunities for medical enterprises from the perspectives of regional industrial layout and policy support. In the cutting-edge academic session, Professor Xu Bing from Beijing University of Chinese Medicine delivered a speech themed Progress and Practice in Continuous Manufacturing of Oral Solid Dosage Forms, introducing the cutting-edge technologies and industry trends in this field; Professor Qu Haibin from Zhejiang University focused on the topic Process Control Technology and Research Progress in Continuous Manufacturing of Solid Dosage Forms, providing a systematic elaboration and in-depth analysis of the key control technologies in continuous manufacturing, which greatly benefited the audience. In terms of enterprise practice and innovative application, Miao Qiyi, Product Technology Director of SHANDONG SMA Pharmatech Co., Ltd., interpreted Regulations on Continuous Manufacturing and Implementation Plan for Application, clearly sorting out the implementation path for technology application; Dong Haizhou, Chief Engineer of the company, further introduced SMA's exploration achievements in Advanced Manufacturing Digital and Intelligent Platform, demonstrating the company's latest progress in the fields of intelligent manufacturing and digital services.

A warm and meaningful special session took place during the conference. Tao Chunlei, Chairman of Anhui Wanbang Pharmaceutical Co., Ltd., awarded a medal of "2024 Preferred Supplier" to SHANDONG SMA Pharmatech Co., Ltd., in recognition of SMA Team's efficient response and professional support when Wanbang was confronted with long-term technical challenges. Prior to this, when Wanbang Pharmaceutical encountered a long-standing unsolved technical problem, SMA immediately dispatched a team of professional technical engineers, who efficiently and accurately overcame the bottleneck issue, effectively ensuring the continuity and stability of production. When accepting the award, Yin Wenping, Chairman and General Manager of SMA, first expressed sincere gratitude to Anhui Wanbang Pharmaceutical. He stated that the company has always taken "process implementation, quality improvement and efficiency enhancement" as its strategic core, persisted in creating real value for customers, and will continue to uphold this concept in the future—wholeheartedly supporting customers' development and continuously fulfilling the service commitment of "customer-centricity". This vivid cooperation case vividly embodies the spirit of in-depth integration of industry, academia and research as well as win-win collaboration advocated by this seminar, and also provides a practical model for the progress of the industry.

Experts in attendance and SMA's R&D team extended the discussion from academic innovation to industrial application, delivering systematic and in-depth reports. These reports comprehensively presented solutions for the continuous manufacturing technology of solid dosage forms, covering the entire process from R&D to industrialization from multiple dimensions, and provided participants with abundant technical references and strategic insights. The successful holding of this seminar has effectively promoted multi-party interaction in the "industry-academia-research-application" ecosystem. It not only broadened the technical perspective but also fully demonstrated SMA's solid technical accumulation and innovative application capabilities in the field of continuous manufacturing of solid dosage forms, injecting new impetus into advancing the application and development of continuous manufacturing technology.