News Center

2025-08-06 16:16:54 source:sma

As a leading brand in China's solid dosage equipment sector, SMA PHARMATECH has always been committed to the implementation of processes and the improvement of quality and efficiency. The company has joined hands with a well-known pharmaceutical factory in Shandong to successfully build a continuous coating production line. Relying on innovative process integration, it has injected SMA's capabilities into enhancing solid dosage production efficiency.

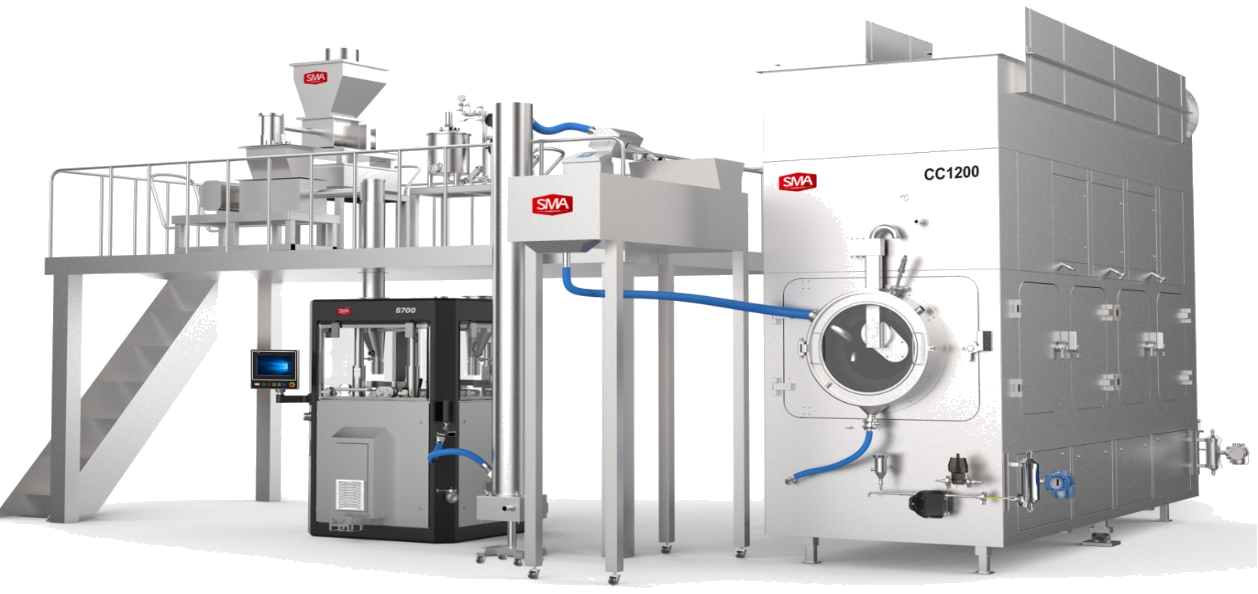

The successfully operational continuous coating production line adopts SMA CC1200 continuous coating machine, S700 tablet press, as well as automatic conveying and weighing systems as its core equipment, realizing the synergy of continuous tabletpress and continuous coating processes. As a key application of pharmaceutical Process Analytical Technology (PAT), it can accurately monitor the coating film thickness in real time, breaking through the lag and error limitations of traditional offline detection. This upgrades quality control from "post-inspection" to "in-process control", laying a solid technical foundation for drug consistency evaluation and ensuring the quality consistency of each batch of products.

At present, the production line has simultaneously advanced the large-scale production of two varieties, innovatively adopting the model of "adaptation to traditional manufacturing + upgrading of continuous systems" — which not only retains the stability of mature processes, but also shortens batch cycles and reduces energy consumption through continuous production. This helps pharmaceutical companies find the optimal solution between compliant production and cost reduction and efficiency gains, truly realizing that "Process Implementation Drives Performance".

Deeply rooted in the field of solid preparation equipment, SMA has always taken "process implementation, quality improvement and efficiency enhancement" as its core. From single machine R&D to whole-line integration, it has continuously addressed production pain points. This project is not only a milestone in technology implementation, but also sends a signal to the industry: the upgrading and iteration of solid preparation production has entered a critical practical implementation phase of "deep, full-process technological collaboration + real-time, precise quality control".

In the future, SMA will continue to anchor itself in the practical effects of processes, deepen the integrated application of continuous production processes, PAT technology, etc., and work with more partners to overcome production difficulties. It will use "Chinese equipment solutions" to drive the solid preparation industry towards greater efficiency, precision and sustainability, making "Improved Quality and Efficiency through Process Implementation" the new industry standard!

Contact Us

Home

Home