Andocksysteme Introduction:

Andocksysteme was founded in 2000, and has a isolated technology center in Badenweiler, Germany. The entire technical team has over 100 years of isolation experience in the fields of pharmaceuticals, chemistry, and life sciences, capable of providing valve products that meet the highest requirements. The core products include airtight split butterfly valves, ball section valves, connectors, samplers, etc;

Since its establishment, it has obtained more than 40 patents, trademarks, and various innovation awards for different types of isolation and packaging technologies; More than 9500 multi-purpose MUT design interface systems have been installed worldwide;

On June 11, 2018, SMA Pharmaceutical Equipment Co., Ltd signed an exclusive agency contract with Andocksystem in China, becoming the exclusive agent of Andocksystem in the fields of pharmaceuticals, chemistry, and life sciences in China.

Product Introduction:

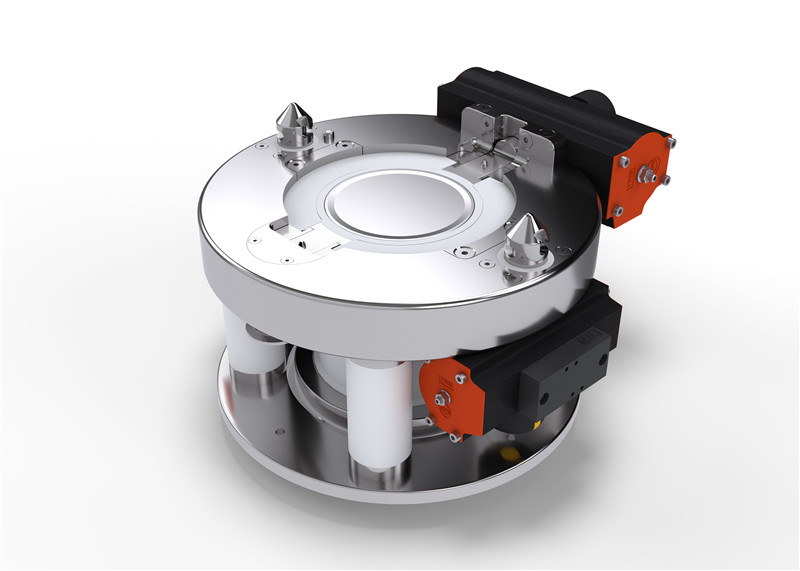

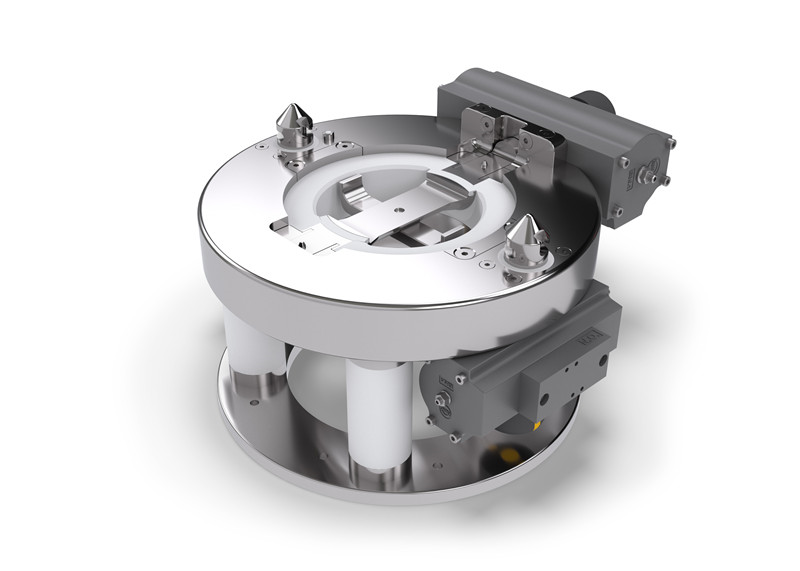

Andock series split butterfly valve, also known as ASBV butterfly valve.

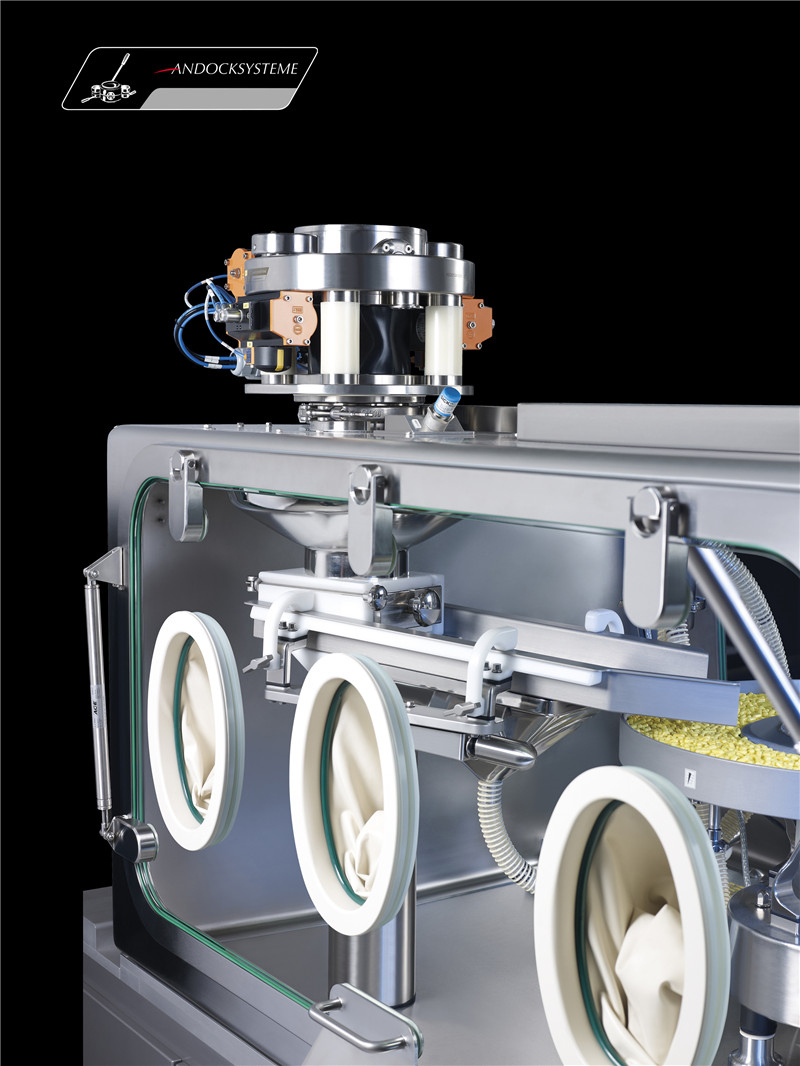

Andock αβ valve, composed of active and passive valves, it is used for material sealing, sterile transportation, avoiding cross contamination, and effectively protecting operators and the operating environment. Suitable for loading, unloading, batching, crushing, sampling, etc. under isolated conditions.

During the docking loading and unloading process, the active valve and passive valve are connected as a whole. After opening the butterfly valve, the docking and distribution of materials are carried out; After the material distribution is completed, the butterfly valve is closed. After loosening the fastening handle, the active and passive valves can be separated, and each equipment can be sealed and transported separately to ensure isolation.

ANDOCK αβ valve can reach OEB5 level, and relevant testing certificates and other documents can be provided to meet the needs of high-end customers at home and abroad.

Product Advantage:

1. Andock split isolated valve dust leakage limit OEL<1 µ g/m ³ (isolation level OEB5), adding a vacuum cleaner can increase the isolation performance by an average of 35%;

2. Proven mature technology, with a maximum allowable deviation of ± 14mm for active valves;

3.180 ° symmetrical design, flexible docking position;

4. Modular design of material contact components, easy to replace;

5. Integrated design of buffer, high degree of valve matching, easy to operate and maintain;

6. Customized, integrated, and highly automated to meet high-end needs.

Size series:

DN50/100/150/200/250/300